Continuous Fiber Additive Manufacturing

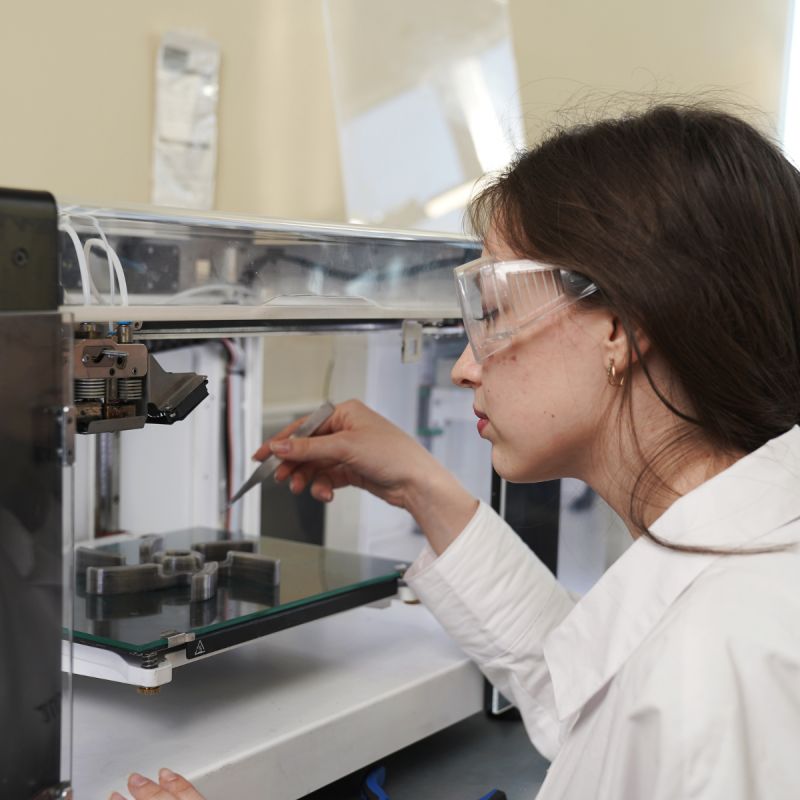

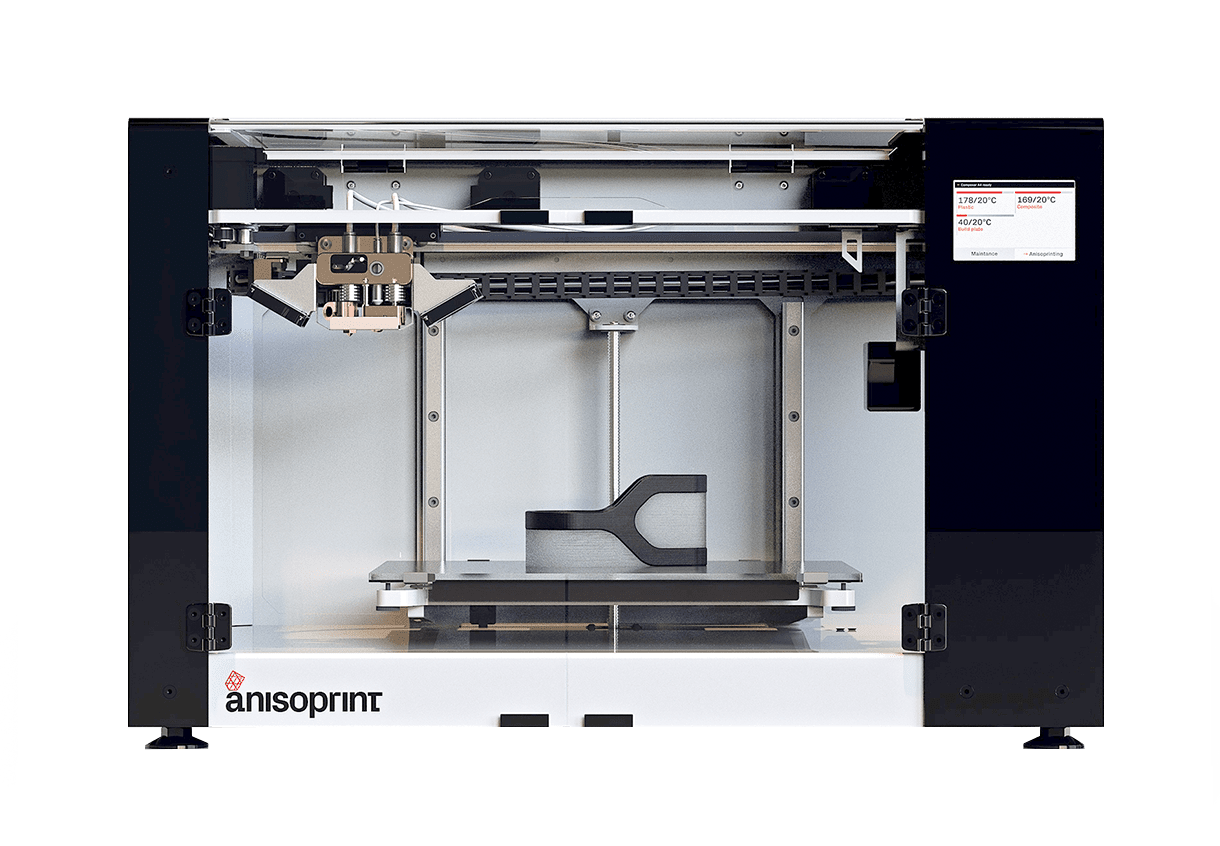

ANISOPRINT Model A4 & A3

Extreme strength parts up to 900MPa with excellent surface quality.

2X STRONGER THAN ALUMINIUM

30x stronger than thermoplastics alone.

LARGE PRINT VOLUMES

Model A4 297 x 210 x 140mm

Model A3 460 x 297 x 210mm

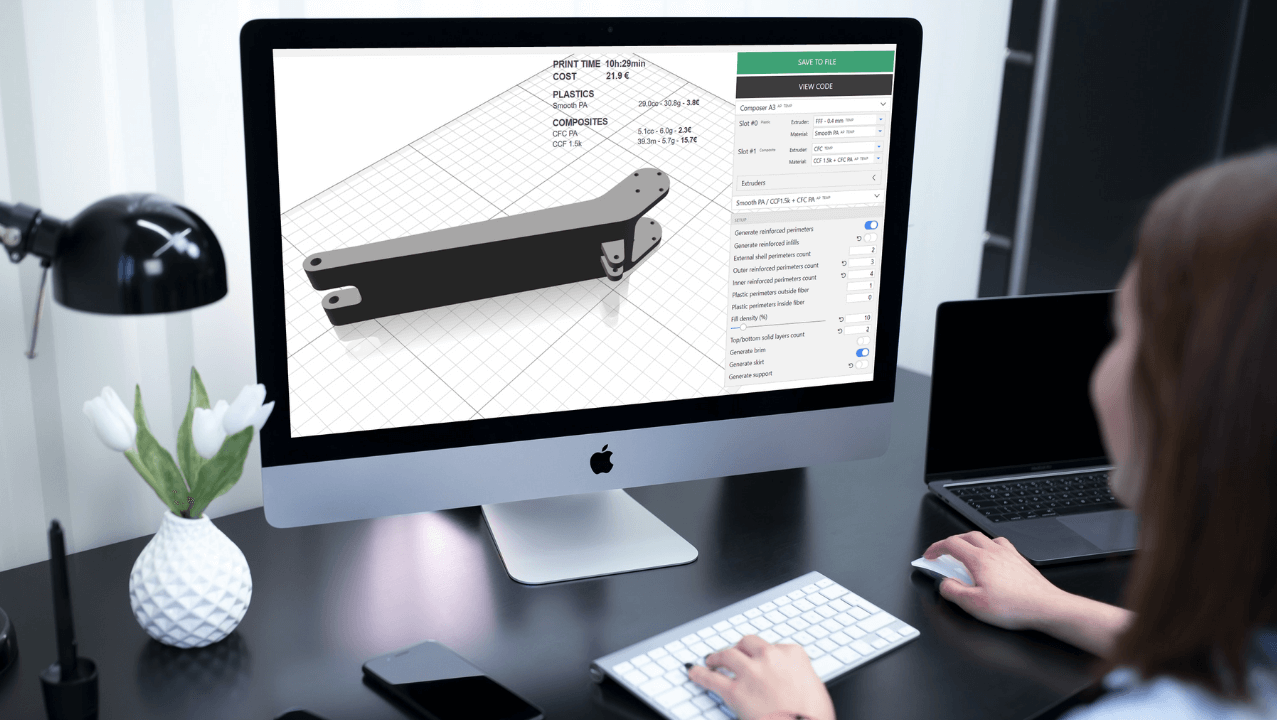

AURA BASIC, NEAT & OPEN

Lattice Reinforcement

Flexible Materials Choice

Fiber Volume Ratio & Trajectories

OEM & OPEN THERMOPLASTICS

OEM SmoothPA, CFCPA & PETG.

Open Thermoplastics >270°C PLA, PETG, PA, PC, ABS, TPU, etc.

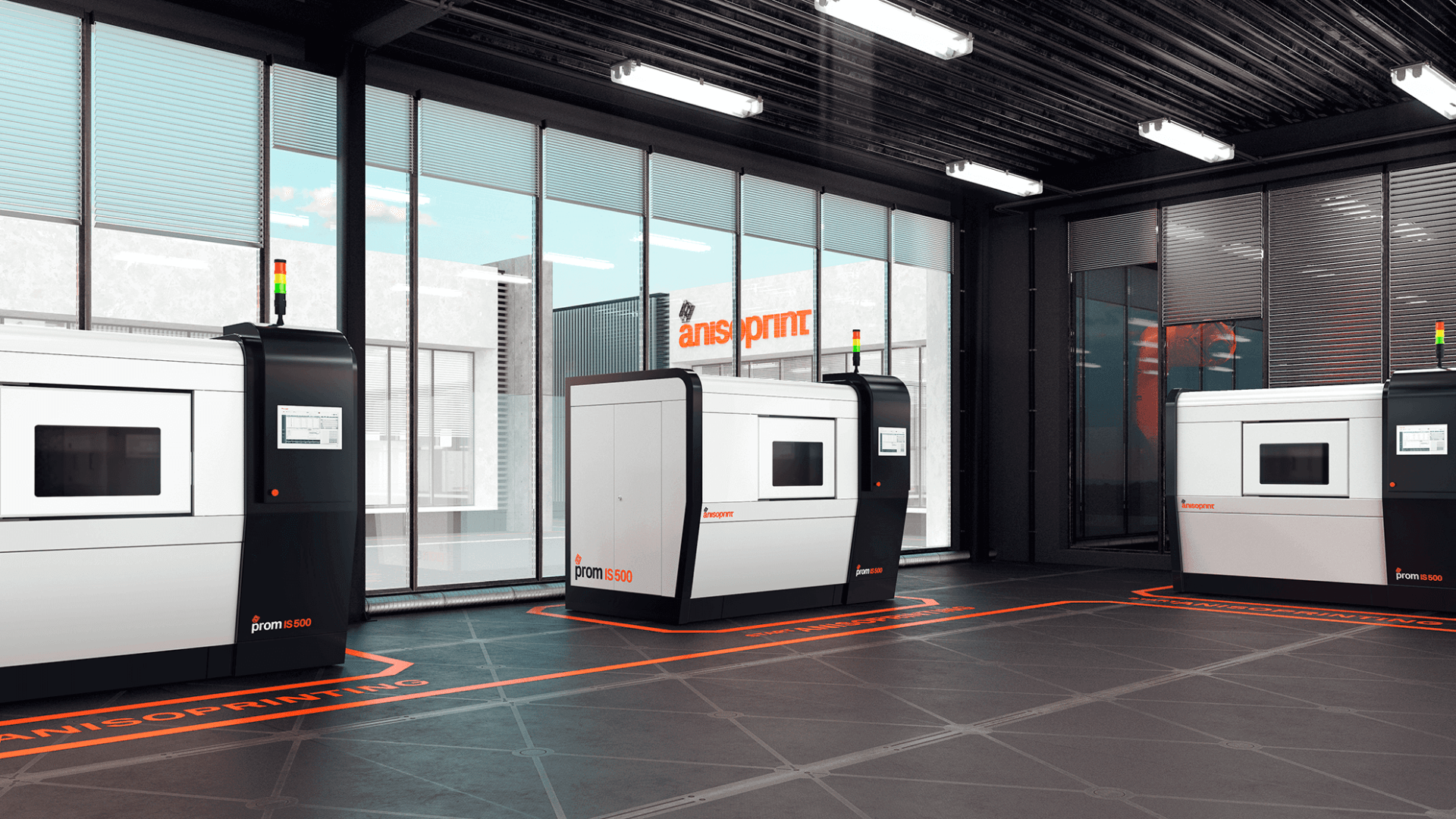

ANISOPRINT Model PROM IS500

24/7 manufacturing optimizing high-temperature thermoplastics and continuous fibers.

2X STRONGER THAN ALUMINIUM

30x stronger than thermoplastics alone.

HIGH TEMPERATURE UP TO 400°C

160°C Heated Chamber.

LARGE PRINT VOLUME

Model PROM IS500 600mm x 420mm x 300mm

AURA BASIC, NEAT & OPEN

Lattice Reinforcement

Flexible Materials Choice

Fiber Volume Ratio & Trajectories

OEM & OPEN THERMOPLASTICS

OEM SmoothPA, CFCPA & PETG.

Open Thermoplastics >400°C PEI, PEEK, PEKK, PAEK, PPSU, PSU, PA, PC etc.

ANISOPRINT Model 6 Axis Robot

6-axis non planar 3D printing provides the ultimate flexibility in terms of possible shapes, and emulates human arm motion for the vital articulation for specific applications.

THE OUTLOOK - DEVELOPMENT STEPS TOWARDS TRULY 3-DIMENSIONAL CONTINUOUS FIBER 3D PRINTING

SOFTWARE

Traditionally 3D printers are actually 2.5D cartesian axis, and true 3D applications increases the complexity of the numeric code. Then robot-part collision detection challenges need to be mitigated before turn-key robot applications can be productized.

Do You Have A Robotic AM Application?

Already we can offer tailored robot solutions and seek partners and beta-testers to work with us to optimize the application and process.

''to be able to add functional strength where needed has reduced the part weight whilst increasing part performance and durability''

Anisoprint Value & Unique Functionalty

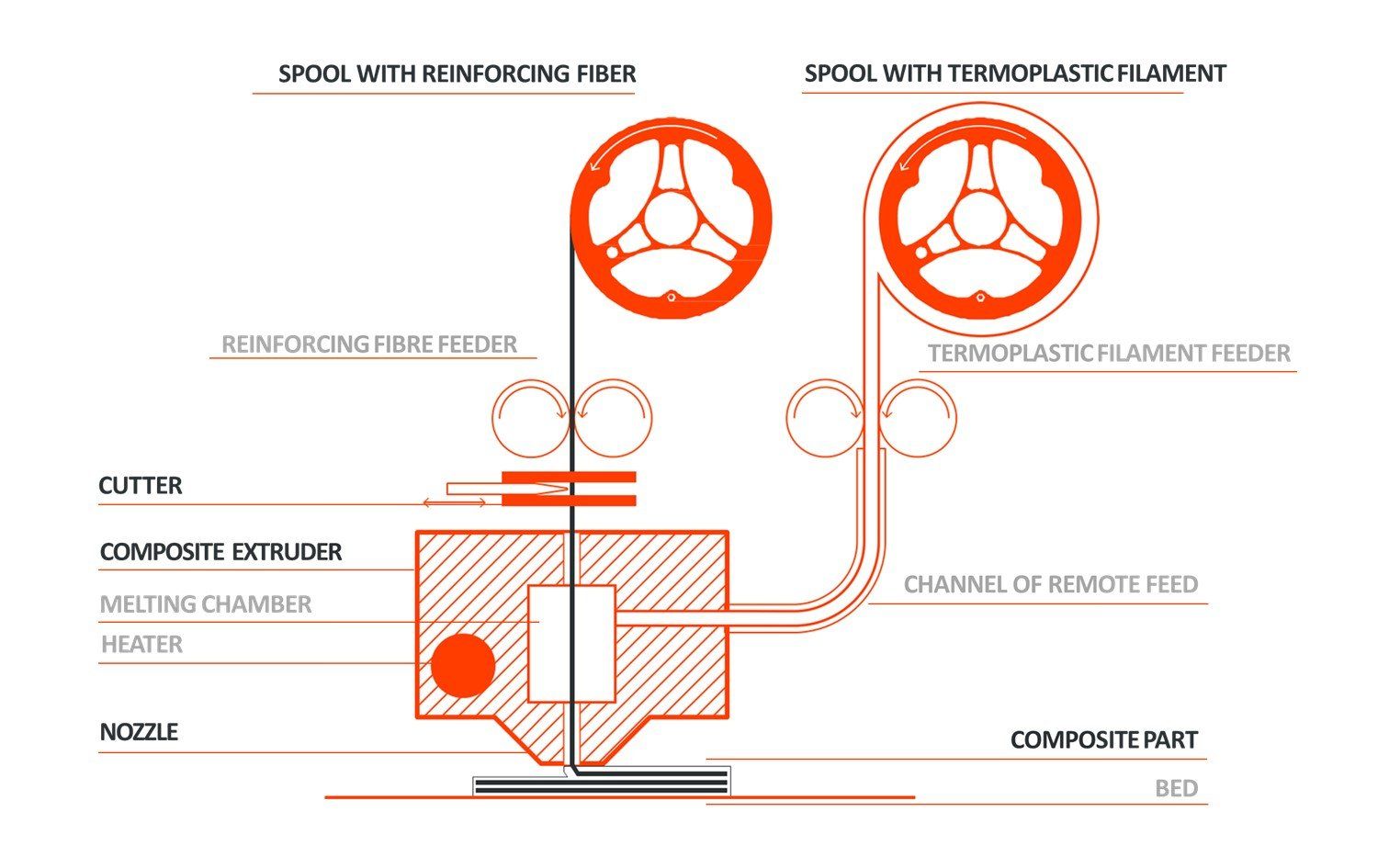

Anisoprint CFC - Composite Fiber Coextrusion

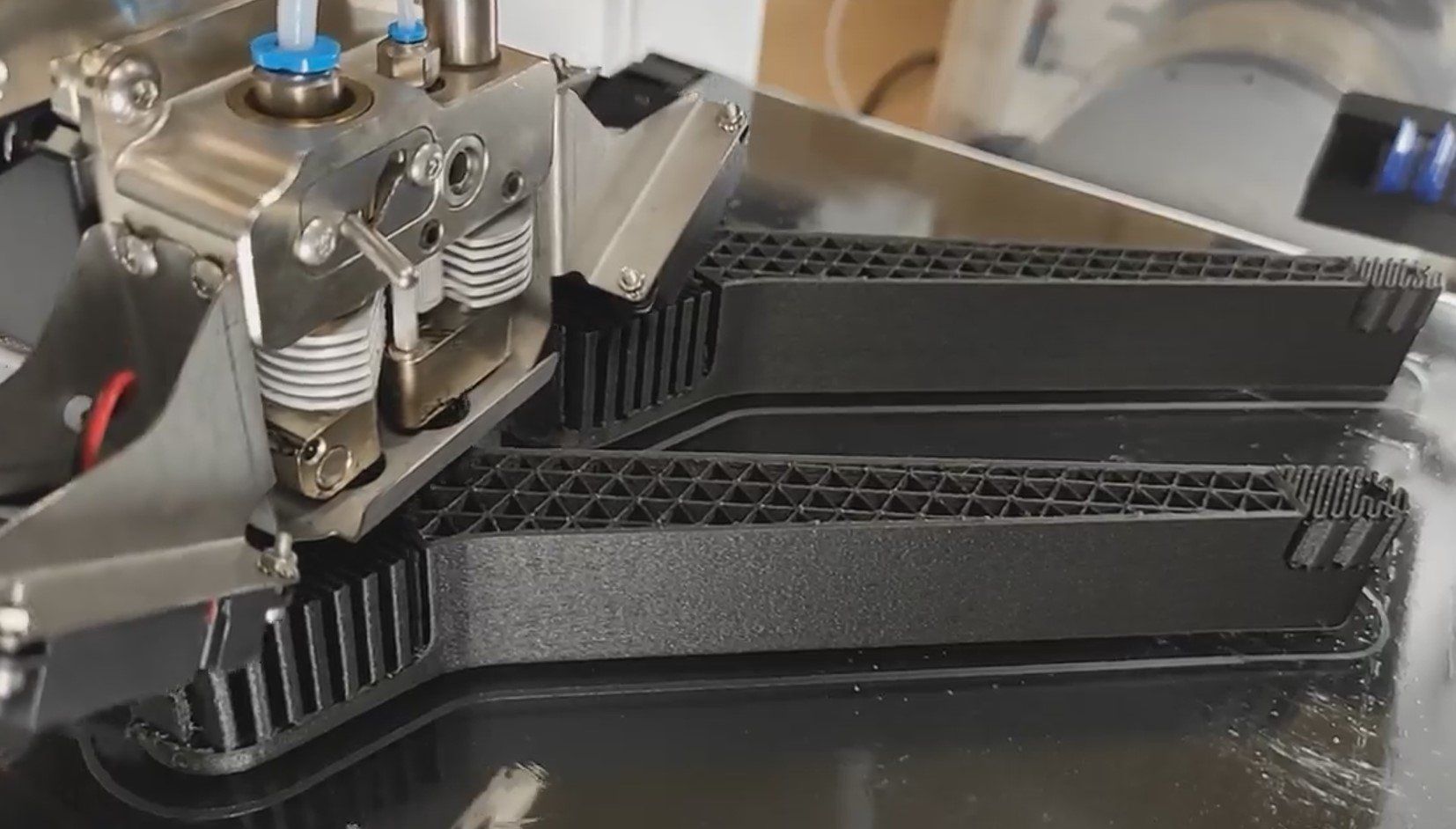

Digital manufacturing has facilitated the design, iteration and production of additive manufactured components within minutes and hours... and Anisoprint has extended this application to yield extreme strength functional components using a range of desktop, industrial and robotic CNC machines.

Optimizing carbon or basalt fibers embedded within FFF/FDM thermoplastic layers results in part strength, stiffness and durability.

These reinforcements enhances mechanical properties and unlock a wide range of applications for aerospace, automotive, aviation, and medical industries.

The thermoset impregnated fiber and a thermoplastic matrix are bound together at the moment of printing, then allowing customizing the feed speed and varying fiber volume ratio for optimum performance.

As the thermoplastic matrix and fibers are delivered separately then bound inside the printing head, users have freedom to choose the component composite makeup to meet their exacting need.

Copyright © All Rights Reserved.